Environmentally Friendly Jewellery Finishing on the Table-top

2 images available

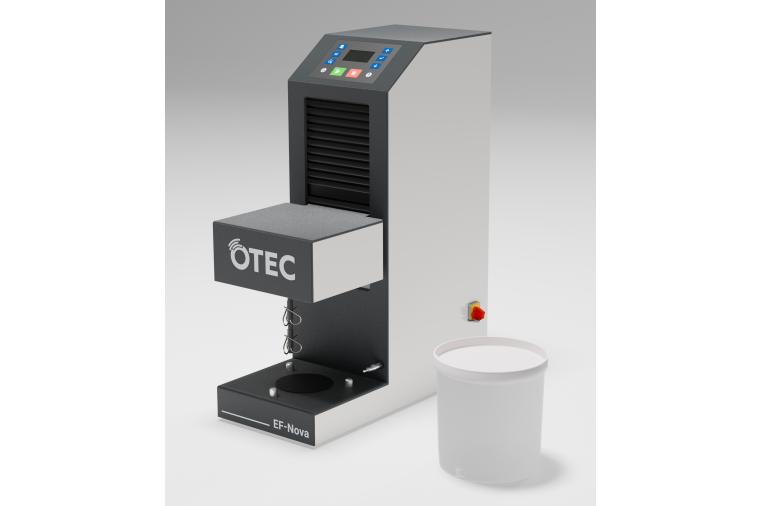

The new EF Nova from OTEC is a small, compact and innovative table-top electro-finishing system. It is designed for the needs of the jewellery industry. Features will appeal to goldsmiths, small manufacturers, artisan makers and craft boutiques. as well as industrial producers. The EF Nova is available in the UK exclusively from Fintek.

A key highlight is the EF Nova’s gold recovery capability – up to 100 percent. This ensures that no valuable material is lost. An essential advantage for sustainable and efficient operations.

Traditional jewellery finishing methods using polishing or acid baths are made obsolete. The EF Nova eliminates the use of toxic chemicals such as cyanide. Better for the environment and worker safety. Instead the new unit employs user and more environmentally friendly electrolytes.

The EF-Nova automates the processing of a range of precious materials. These include yellow, red, and white gold, as well as silver, brass, and stainless steel. It can also process challenging alloys such as white gold-palladium and titanium. All with exceptional precision. Reaching into intricate geometries and hard-to-reach areas. This is where traditional methods often fall short.

A capacity to process up to six rings at once, EF Nova increases efficiency in workshops. For custom needs, specialised holders for rings, bracelets or pendants are also available.

Quick and straightforward commissioning saves time and reduces training effort. This makes the EF Nova a simple plug and play unit. A user-friendly navigation system guides the operator through the functions. This minimises errors and increases production efficiency. Eight pre-installed programs enable use without special prior knowledge. Allowing beginners and smaller goldsmith workshops to get to work right away.

The process container stores information about the process media and operating hours. It enables the corresponding functions. Through automated assignment, only liquid electrolytes are permitted. Quick electrolyte changes ensure minimal downtime and continuous productivity.

The EF Nova process duration is around 30 minutes or less. This is regardless of the material and delivers outstanding smoothing and polishing results. The machine reduces labour-intensive manual tasks. Including polishing and grinding by up to 90 percent.

More Information

Jamie Phillips, General Manager, Tel. +44 (0)1706 283 927

Fintek, Halter Inn Works, Holcombe Brook, Bury, Lancashire, BL0 9SA

Email: jamie@fintek.co.uk Web: www.fintek.co.uk

Release issued: April 14, 2025

Email this page

Environmentally Friendly Jewellery Finishing on the Table-top

Environmentally Friendly Jewellery Finishing on the Table-top